ESAB Purchases MPC for Use in HLAW Process

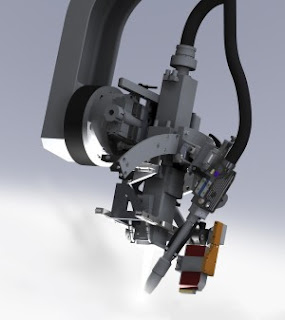

ESAB has completed the purchase of the Master Process Controller (MPC) from Applied Thermal Sciences (ATS) for use in its hybrid laser-arc-welding (HLAW) process. The MPC is a patented real-time control system for managing the laser, MIG/MAG welding equipment and motion system that carries the laser and MIG/MAG welding heads. ESAB has been working with ATS for more than six years to develop this adaptive welding control system for hybrid laser arc welding.

Now that ESAB has acquired the MPC, its Hybrio hybrid laser arc-welding equipment can be used on thicker materials, larger workpieces and joints with wider gaps. During the welding process, the MPC uses sensors to monitor the joint fit-up, weld geometry and welding conditions, making adjustments as necessary to ensure that the process achieves uniform fill, consistent penetration and excellent weld quality for the entire length of the weld. With its improved tolerance of gap variations, the hybrid laser-arc-welding process enables customers to reduce the time and costs associated with joint preparation, post-weld operations and rework.

ESAB is committed to the HLAW process and has put in place an infrastructure so that it can manufacture, market, sell and support this process. In addition, the company will continue developing the process to create hybrid laser-arc-welding systems that will help customers maximise productivity and maintain quality. Available in gantry, robotic and specialised automated systems, ESAB's Hybrio is suitable for use in a range of industrial applications.

Now that ESAB has acquired the MPC, its Hybrio hybrid laser arc-welding equipment can be used on thicker materials, larger workpieces and joints with wider gaps. During the welding process, the MPC uses sensors to monitor the joint fit-up, weld geometry and welding conditions, making adjustments as necessary to ensure that the process achieves uniform fill, consistent penetration and excellent weld quality for the entire length of the weld. With its improved tolerance of gap variations, the hybrid laser-arc-welding process enables customers to reduce the time and costs associated with joint preparation, post-weld operations and rework.

ESAB is committed to the HLAW process and has put in place an infrastructure so that it can manufacture, market, sell and support this process. In addition, the company will continue developing the process to create hybrid laser-arc-welding systems that will help customers maximise productivity and maintain quality. Available in gantry, robotic and specialised automated systems, ESAB's Hybrio is suitable for use in a range of industrial applications.

Comments