Software Supports Injection-Moulding Objectives

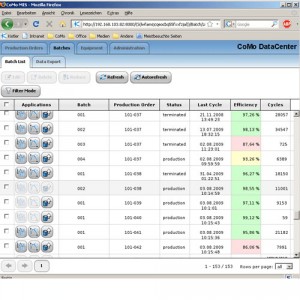

The Como Datacenter Type 2829B is a proprietary software designed for use with the Kistler Como Injection system, helping to support zero-defect plastics injection-moulding manufacturing objectives. It is designed to streamline and simplify the data-collection operations of the Como Injection data-acquisition system, by allowing it to automate information flow during plastics injection-moulding production. The Como Datacenter features an intuitive interface and its own 4GB storage database, allowing the user to view, analyse and store product-manufacturing data.

It also offers real-time statistical analysis capabilities and the ability to output a clear and comprehensive status overview within a hectic production environment. If the database is required to be used without size restriction, software may also be installed and run with a full version of Microsoft SQL Server. Kistler Como Datacenter provides plastics injection-moulding manufacturing personnel, such as operations managers, shift supervisors and quality management, with accurate and rapid insight into production status.

The system uses multiple variables associated with the production order, with easily and cost-effectively exported data for additional analysis or incorporation into ERP systems. Subsets of collected data, such as good/bad, maximum/minimum, integral or other variables produced by Como Injection may also be identified and analysed. Software is compatible with most global industry versions of Microsoft Windows 7, with multiple Como Datacenter user licences available upon request.

It also offers real-time statistical analysis capabilities and the ability to output a clear and comprehensive status overview within a hectic production environment. If the database is required to be used without size restriction, software may also be installed and run with a full version of Microsoft SQL Server. Kistler Como Datacenter provides plastics injection-moulding manufacturing personnel, such as operations managers, shift supervisors and quality management, with accurate and rapid insight into production status.

The system uses multiple variables associated with the production order, with easily and cost-effectively exported data for additional analysis or incorporation into ERP systems. Subsets of collected data, such as good/bad, maximum/minimum, integral or other variables produced by Como Injection may also be identified and analysed. Software is compatible with most global industry versions of Microsoft Windows 7, with multiple Como Datacenter user licences available upon request.

Comments