Hitachi Introduces the Next Economical Simple Inverter

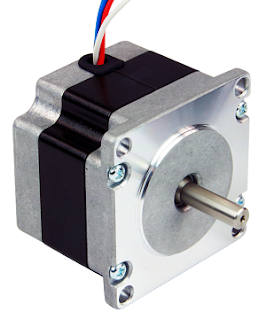

Hitachi America, Ltd., Industrial Components & Equipment Division, today announced the launch of its next generation inverter, the NE-S1. Hitachi America, Ltd. is now pleased to offer these economical and simple to use inverters in the popular HP range of 1/2 to 3 hp. The NE-S1 is designed to be ultra-compact to meet the needs of both OEMs and System Integrators. The NE-S1 variable frequency drive offers the end user and integrator the ability to use the control as is out of the box, with popular preconfigured and simple defaults settings. In addition, a wide variety of options are available to configure the control for a specific application. These powerful pre-configured inverters allow for the use of remote mounted speed potentiometers, contacts or switches, and preset speed selections without any parameter changes thus saving time during the installation and integration process. A wide variety of keypad options are also available to make the NE-S1 inverter a full keypad ...