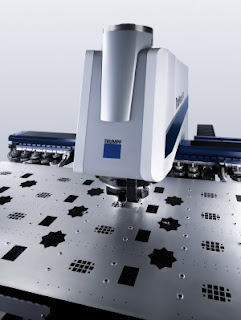

Trumpf Introduces Electric Punching Machine

The Trupunch 3000 electric punching machine from Trumpf offers efficient, skeleton-free punching made possible by powerful nesting software combined with the option to rotate parts and scrap. The result increases reliability in several areas, according to the company. For example, parts are cleanly separated from the skeleton, the operator no longer needs to remove leftover material from the table, and the machine automatically separates finished parts from the scrap. Production costs are also reduced in the region of 10 per cent because less material is required.

The Trupunch 3000 introduces Trumpf's electric punching head, which is said to bring several benefits. It is quieter in operation and uses little power in standby mode. When it is punching it is more energy efficient, using 2kW of power per hour less than its predecessor. The punching head is also more productive, according to Trumpf. Tools are rotated at higher speed giving more benefits - threads are formed quicker, for example. The absence of the hydraulic head allows the Trupunch 3000 to occupy a footprint that is smaller than the previous-generation machine by 5m2 (about 13 per cent). With the quality of processed surfaces becoming increasingly important, Trupunch 3000 has been designed to handle material as gently as possible. A key feature in this regard is the machine's parts chute, which ejects cut components horizontally into a collection bin, stacking them evenly.

Workpieces measuring up to 500 x 500mm are discharged, scratch-free, via the parts flap. The Trupunch 3000 can be operated with standard containers so material logistics can be uniform throughout the production process. It is also compatible with the Trumpf Sheetmaster, which includes part picking and can automatically remove individual parts and stack them in a predetermined layout. Further automated options include Sortmaster Box Linear, a sorting unit for small finished parts, and Disposemaster, which separates all process waste according to material type.

The Trupunch 3000 introduces Trumpf's electric punching head, which is said to bring several benefits. It is quieter in operation and uses little power in standby mode. When it is punching it is more energy efficient, using 2kW of power per hour less than its predecessor. The punching head is also more productive, according to Trumpf. Tools are rotated at higher speed giving more benefits - threads are formed quicker, for example. The absence of the hydraulic head allows the Trupunch 3000 to occupy a footprint that is smaller than the previous-generation machine by 5m2 (about 13 per cent). With the quality of processed surfaces becoming increasingly important, Trupunch 3000 has been designed to handle material as gently as possible. A key feature in this regard is the machine's parts chute, which ejects cut components horizontally into a collection bin, stacking them evenly.

Workpieces measuring up to 500 x 500mm are discharged, scratch-free, via the parts flap. The Trupunch 3000 can be operated with standard containers so material logistics can be uniform throughout the production process. It is also compatible with the Trumpf Sheetmaster, which includes part picking and can automatically remove individual parts and stack them in a predetermined layout. Further automated options include Sortmaster Box Linear, a sorting unit for small finished parts, and Disposemaster, which separates all process waste according to material type.

Comments